In the grand tapestry of modern industry, fluid is the surging "blood", connecting the roaring workshop of petrochemical industry, the blazing production line of iron and steel metallurgy, and the vertical and horizontal pipe network of urban water supply and drainage, and maintaining the green defense line of environmental protection. The accurate capture of traffic data is the core key to controlling process accuracy, optimizing resource allocation, and reducing production costs.

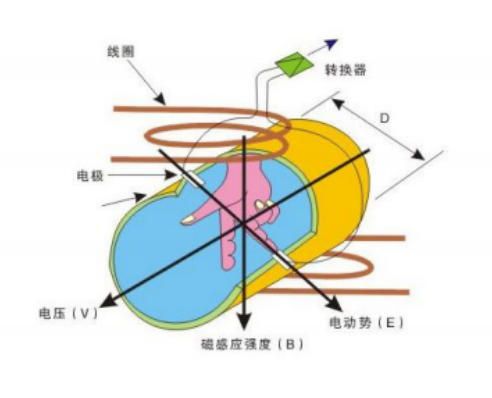

Electromagnetic flow meter, this intelligent equipment rooted in Faraday's law of electromagnetic induction, has become the "accurate eye" in the field of industrial fluid measurement with its innovative design, excellent and stable core performance and flexible characteristics that adapt to thousands of working conditions, injecting a steady stream of kinetic energy into the upgrading of industrial intelligence.

Traditional flow meters have long been constrained by the physical properties of fluids, and subtle changes in density, viscosity, and temperature may lead to measurement deviations, and the existence of flow-blocking components not only causes considerable energy loss, but is also more prone to slurry and impurities to block and wear, making maintenance work in a dilemma.

The electromagnetic flow meter breaks this deadlock with a disruptive design, and there is no obstruction in the measuring tube, as if opening up an unimpeded "green channel" for the fluid, which not only completely eliminates the energy waste caused by pressure loss, but also shows a natural adaptation advantage to liquid-solid mixed fluids such as slurry and mineral slurry. There is no need to worry about clogging failures caused by impurity accumulation, and it can still maintain smooth operation even in complex media environments with high concentrations and high viscosity, calmly solving measurement problems that are difficult to overcome with traditional flow meters.

In terms of measurement accuracy and range, the electromagnetic flow meter truly shines. Its measurement process is completely undisturbed by changes in fluid density, viscosity, temperature, pressure and conductivity, and can accurately capture every trace flow change no matter how the working conditions fluctuate, with an accuracy level of up to 0.5 or 1.0, meeting the strict requirements of industrial production for measurement accuracy.

The flow measurement range is an astonishing 1500:1, and the flow rate measurement covers a wide range of 0.1m/s to 15m/s, from trickles to rushing torrents. It also supports users to flexibly adjust the range online according to actual production needs, without disassembling the equipment or interrupting the production process, which greatly improves the adaptability and flexibility of the equipment's working conditions, and perfectly meets the flow measurement needs of different production stages and different process requirements.

Under the wave of industrial intelligence, flow measurement equipment not only needs an accurate measurement core, but also has the characteristics of intelligent interconnection and convenient operation. The converter of the electromagnetic flow meter is equipped with a 32-bit embedded microprocessor, which adopts fully digital signal processing technology, which has fast computing speed and strong anti-interference ability.

Even in the complex electromagnetic environment of the industrial site, it can effectively filter out various interference signals, ensure the stability and reliability of measurement data, and provide solid data support for subsequent data analysis and process regulation.

In terms of operation and visualization experience, the equipment is equipped with a high-definition backlit LCD display, supports free switching between Chinese and English menus, and the interface design is simple and intuitive, and various parameters and measurement data are clear at a glance.

For high-risk working environments or long-distance operation scenarios, the optional infrared hand operator can be equipped with a high-speed communication rate of 115KHZ to achieve non-contact parameter setting and function debugging, and all operations can be completed without close contact with the equipment, which not only improves work efficiency, but also adds an important guarantee to the personal safety of operators.

In terms of data transmission and integration, electromagnetic flow meters show strong compatibility and scalability. It supports a variety of digital communication signal outputs such as RS485-MODBUS and Hart, which can be seamlessly integrated into industrial automation control systems, easily realizing remote monitoring, real-time transmission and centralized management of traffic data, and paving the way for enterprises to build smart factories and realize digital management and control.

Built-in three independent meters, which can accurately record forward and reverse accumulation and difference accumulation to meet the multi-dimensional needs of production accounting. At the same time, it is equipped with a power-down clock function, which can accurately record the duration of the power loss even if it encounters a sudden power outage, and automatically connect the data record after the power supply is restored to ensure the continuous and complete data and provide reliable support for production accounting.

The measuring media in industrial production are complex, including highly corrosive fluids such as strong acids and alkalis, strong abrasive slurries containing solid particles, and food and pharmaceutical media with strict hygienic requirements. In order to cope with the personalized needs of multiple working conditions, the electromagnetic flow meter shows ingenuity in the selection of materials and provides a "tailor-made" precise adaptation solution.

The lining materials cover a variety of high-quality materials such as polyneoprene, polyurethane rubber, polytetrafluoroethylene (PTFE), F46, PFA, etc. Polyneoprene has excellent elasticity and wear resistance, and is suitable for general water, sewage and lightly abrasive mud.

The electrode materials have been strictly screened, and high-quality materials such as molybdenum stainless steel, tungsten carbide, Hastelloy alloy, titanium and other high-quality materials are selected, and flexibly matched according to the corrosiveness and wear of the medium. Molybdenum-containing stainless steel is suitable for weakly corrosive conventional media, tungsten carbide has outstanding performance against strong wear slurries, and Hastel alloy, titanium, etc. can be stable in different types of corrosive fluids, ensuring that the electrode maintains stable performance under various extreme working conditions and effectively extends the service life of the equipment.

In terms of specifications, the nominal diameter of the electromagnetic flow meter covers DN6 to DN3000mm, and the pressure range extends from 0.6MPa to 42MPa, which can meet the measurement needs of various types from fine chemical pipelines with small flow to large-scale industrial pipe networks.

Industrial production has extremely high requirements for the reliability and safety of equipment, and electromagnetic flow meters fully consider this core requirement in the design and manufacturing process to build a solid line of defense for safe production with multiple guarantees. The instrument adopts SMD devices and surface mount (SMT) technology, with high circuit reliability, with perfect self-test and self-diagnosis functions, which can monitor key indicators such as air traffic control status and excitation system operation in real time, and alarm in time when abnormal, which is convenient for staff to troubleshoot and deal with in time, and minimize fault losses.

For the special needs of high-risk industries such as petrochemical and mining, the product can be configured with explosion-proof design to meet the requirements of safe operation in flammable and explosive environments. In terms of grounding and lightning protection design, the equipment provides a standardized grounding scheme, and the converter terminal grounding point is reliably grounded after being connected to the shell, and with the lightning protection gas discharger, the lightning current can be quickly introduced into the earth to avoid equipment damage and personnel safety risks.

In terms of installation and maintenance, the electromagnetic flow meter shows great flexibility and convenience. It has loose requirements for straight pipe sections, supports a variety of installation methods such as horizontal and vertical, and the plug-in design allows installation and maintenance without interrupting pipeline operation without complex pipeline modifications. Daily maintenance is simple, only regular electrode contamination and grounding are checked, greatly reducing maintenance costs.

From industrial production workshops to urban pipe networks, from pharmaceutical and food clean workshops to water conservancy and irrigation projects, electromagnetic flow meters provide strong technical support for flow measurement and control with accurate, stable and reliable performance. As the core equipment under the wave of Industry 4.0, it helps enterprises achieve refined management, improve production efficiency and product quality, and become an ideal choice for modern industrial fluid measurement, writing a new chapter of accuracy and reliability on the road of industrial intelligent upgrading.