In diverse industrial scenarios such as spraying, cleaning, cooling, and dust removal, nozzles are core components that control fluid trajectory and efficiency. Their operational stability and maintenance convenience directly affect the production line's efficiency pulse and cost red line. The disassembly of traditional nozzles often requires the support of specialized tools, which not only consumes time and effort but also makes repeated disassembly operations more likely to wear out the interface seal structure, leading to leakage, flow deviation, and other problems, creating hidden dangers for continuous production of enterprises.

Mid-crown Fluid Technology.,Ltd, a company deeply rooted in the field of industrial fluid components, with an unwavering pursuit of craftsmanship quality, uses innovative design as its spear and craftsmanship technology as its shield, creating quick-release nozzles to precisely break through long-standing pain points in the industry.

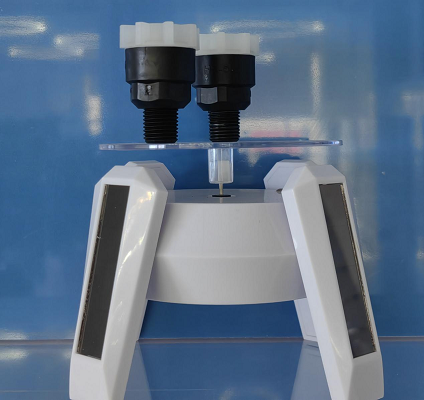

The Mid-crown quick-release nozzles feature a two-piece quick-release design, divided into the nozzle and the main body, which can be manually assembled without any tools. Three positioning latch points allow the nozzle to be accurately rotated into position, avoiding nozzle loosening during on-site work, effectively ensuring product quality. What used to take dozens of minutes to dismantle, clean, and reinstall has now been compressed into just tens of seconds, significantly reducing downtime and laying a solid foundation for efficient operation of the production line.

The main body of the PVDF nozzle is made of PVDF material, which has excellent acid and alkali corrosion resistance, can withstand erosion by most organic solvents and strong chemical media, and simultaneously possesses good high-temperature resistance and mechanical strength, capable of coping with harsh working conditions such as high pressure, high temperature, and strong corrosion in industries like chemicals, electroplating, and environmental protection, effectively extending the service life of the nozzle, reducing equipment replacement and maintenance frequency.

The internal flow channel of the nozzle is precision CNC machined and polished, with smooth inner walls free of burrs, ensuring stable fluid passage, preventing flow fluctuations and uneven atomization caused by rough channels, achieving precise control of flow and spray angle, uniform and delicate atomization effect, controllable impact force, perfectly matching the stringent production requirements of various industries. In addition, the internal gasket offers different options such as EPDM, Viton, and Viton-F, suitable for various chemical processes, and special structural designs ensure tight coupling between the nozzle head and base, preventing water leakage and ensuring long-term stable operation of the equipment.

In terms of material selection, the Mid-crown quick-release nozzle achieves customized multi-material pairing for key components: the TIP part uses PVDF material, possessing outstanding acid and alkali resistance and anti-corrosion performance; the central blade can choose PP, PVDF, PVC materials, while the base covers PVDF, PP, U-PVC (QFSA, QFWG), etc., providing three choices for gaskets including EPDM, Viton, and Viton-F. Rich material combinations enable the nozzle to handle different medium characteristics in wetting chemical drugs, fire-fighting dust suppression, gas cooling, and other scenarios, maintaining stable usage even under highly corrosive and demanding chemical processes.

At the same time, the nozzle features an X-shaped central blade (CORE) design, increasing the diameter of foreign object pass-through, effectively reducing clogging risks, and making fluid turbulence more uniform, resulting in consistent mist particle distribution; spray types cover solid cone, hollow cone, fan shape, and others, meeting the spray needs of semiconductor and printed circuit board etching, developing process, as well as gas or exhaust cleaning, tank cooling, and other scenarios, perfectly adapting to high-precision manufacturing processes requiring extremely uniform misting.

From gas, exhaust, and dust washing devices and tank cleaning, to tank, machinery, metal cooling operations, to wetting chemical drugs, fire-fighting dust suppression dispersion stages, up to high-demand semiconductor and printed circuit board etching, developing processes, the Mid-crown quick-release nozzle stands out with "high-efficiency assembly + stable performance + clog-resistant durability" advantages, becoming a preferred solution for many manufacturing companies to optimize their production processes.

In chemical dispersion scenarios, its corrosion-resistant material and uniform atomization effect ensure accurate delivery of chemical media; in semiconductor etching processes, clog-resistant design and high-uniformity misting help improve product processing accuracy; in environmental protection dust removal fields, diverse spray modes can flexibly adjust according to dust characteristics, greatly improving dust removal efficiency.

Driven by innovation to boost efficiency, and built on quality to establish industry reputation, Mid-crown Fluid consistently focuses on R&D and manufacturing of industrial fluid components, from structural design to material selection, every step embodies craftsmanship. Based on deep insights into different industry working condition demands, Mid-crown Fluid independently developed KingSpray nozzles, ISJJX spray nozzles, American nozzles, Lechler nozzles, and Universe nozzles among multiple quick-detachable nozzle products, forming a rich self-developed product line.

KingSpray nozzle main features:

Wide-angle (15°-110°) flat fan nozzle misting, achieving uniform distribution;

Offers plastic fan misting nozzles (suitable for light applications) or metal nozzles (for extreme environments) as options;

Low-clog design, lasting fan misting performance;

Suitable for agricultural and industrial systems, usable as a flat fan misting nozzle.

ISJJX spray nozzle main features:

Provides precise spraying at moderate flow rates, ideal for cleaning and rinsing applications;

Made of robust stainless steel, ensuring stable operation in industrial environments;

Full-cone nozzles (achieving uniform liquid distribution) and solid-cone nozzles (for high-impact sprays) by the professional spray nozzle manufacturers;

Combines durability and reliability in cooling, rinsing, and firefighting areas.

American nozzle main features:

Optimized for low-flow, high-precision applications, featuring excellent atomization effects and fine droplet control capabilities;

Suitable for fogging cooling, lubrication, and coating processes;

Made of stainless steel, brass, or specialty polymers;

Stable spray angles and clog-resistant designs ensure reliable long-term operation.

Lechler nozzle main features:

Designed for high efficiency and durability;

Suitable for processes requiring hollow cone nozzles or hollow cone mists;

Applicable to cooling, coating, and gas purification;

Adjustable flow and pressure ranges maximize performance and reduce waste.

Universe nozzle main features:

Specifically designed for ultra-durable, high-pressure applications, resistant to severe wear and harsh operating conditions;

Suitable for heavy-duty descaling, water jet cutting, and sandblasting cleaning tasks;

Made of tungsten carbide or ceramic materials, performing far better than standard models in erosive environments;

Offers fan, cone, and direct current spray forms, minimizing downtime with stable performance.

These series of nozzles' sustained popularity vividly demonstrates Mid-crown Fluid's commitment to craftsmanship quality and technological innovation: KingSpray types of nozzle stand out with wide-angle (15°-110°) uniform fan misting, dual-material nozzles adaptable to light and heavy-duty conditions, low-clog design ensuring stable operation, achieving over 60% repurchase rate in general-purpose fields; ISJJX spray nozzles based on stainless steel hard-core materials provide precise control at moderate flows, freely switching between double-cone misting modes, showcasing reliable performance in cooling, rinsing, and firefighting scenes, firmly occupying top positions in industrial cleaning sectors;

American nozzles specialize in low-flow, high-precision needs, offering diverse materials resistant to corrosion, excelling in micron-level atomization and droplet control, becoming preferred tools in precision manufacturing; Lechler nozzles embody energy-saving concepts, covering broad hollow cone mists, adjustable flow and pressure for maximum performance and reduced waste in chemical and environmental protection industries; Universe nozzles use tungsten carbide or ceramic abrasion-resistant materials, enduring high-pressure wear and harsh conditions, versatile spray forms suited for heavy-duty tasks, stabilizing high-end heavy industry production defenses. The success stories of these self-developed products are the best treatment to Mid-crown’s dedication to craftsmanship and market victory through innovation.